BMG

Liquid metal is bulk amorphous alloy, also called bulk matal glass. Its microstructure is a kind of long-range-disordered with short-range-ordered. During the rapid cooling solidification process, there is no time for metal to crystallize. In some sense, amorphous structures are free from defects and have no dislocation defect and grain boundaries as crystal materials does .So liquid metal will have more unique excellent characteristics compared with crystal materials in some aspects.

Application

The application of liquid metal material are determined by its properties and molding methods, the main application of liquid metal materials are listed below: telecommunication parts, samrt wearable,bathroom products, biomedical applications, security tools, auto parts, sports equipment as well as others.

Product Feature

1、High Strength High Hardness (To improve scratch resistance and deformation degree)

2、High Elasticity(To meet some special requirements)

3、Good Corrosion Resistance(Never rust and extend life cycle)

4、Good Biocompatibility And Antibacterial Activity(To protect you and family member’s health)

5、Complex thin Components(To enrich ID designs and diversify products)

6、Poor Electrical and Heat Conductivity(To avoid being scalded and enhance customer experience)

7、Advanced Metal Texture(To improve product grade)

The price is moderate and can be produced in large quantities. Liquid metal belongs to brittle material, and its failure mode is mainly fracture. Therefore, it should be avoided as far as possible to be used in some key stress components, such as aircraft and automobile, which require high safety performance and are the main stress components.

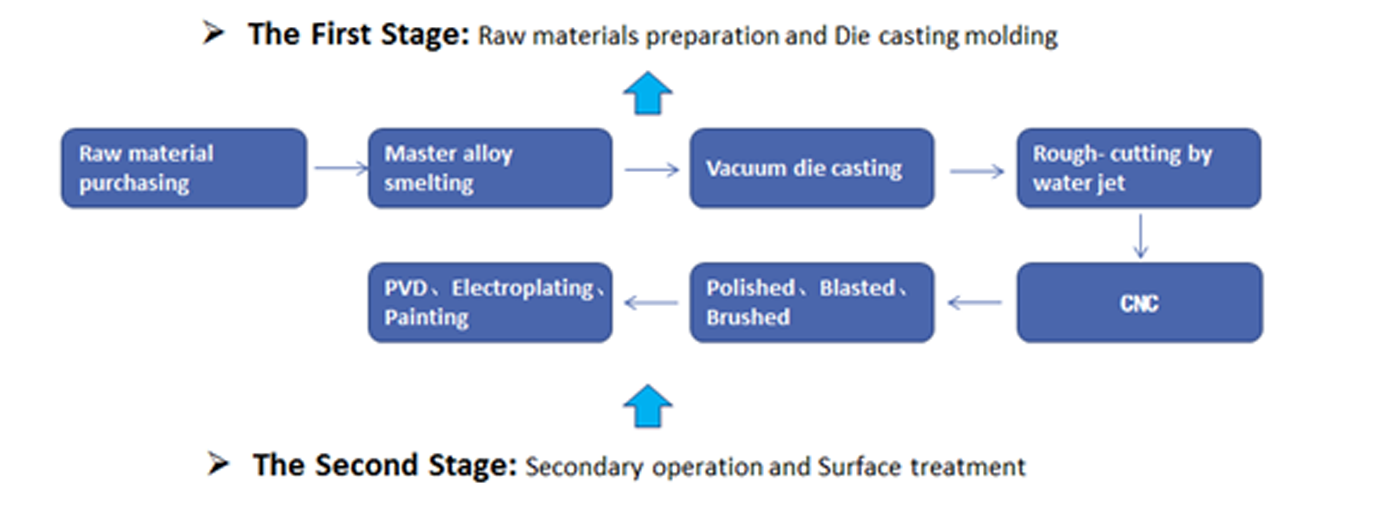

Process

Material Property

Physical Properties : Lower melting point ; Higher resistivity; Low heat conductivity

Chemical properties: excellent corrosion resistance to various media; extremely difficult to be oxidized at room temperature

Mechanical properties: high strength and hardness; strong wear resistance and scratch resistance; high elastic limit; almost no plastic deformation

Processing properties: good workability, no work hardening; strong wear resistance and scratch resistance; good fluidity, forming thin-walled parts with complex structure; good superplasticity near Tg temperature

沪公网安备 31011302002267号

沪公网安备 31011302002267号